Loading... Please wait...

Loading... Please wait...FASHION & STYLE

Aesthetics

This refers to the combination of color, detailing (like patterns) or knitted-in design (like stripes and argyles). Aesthetic constructions like ribs or mesh presents an almost unlimited array of styling and design possibilities.

Colour

Socks always follow colour trends very closely and can offer lines of merchandise that coordinate with all current ready-to wear colour styles. With nowadays’ dyes and dyeing methods, there is virtually no colour, colour effect or colour shade that cannot be achieved in a sock.

Detailing

Detailing consists of any material applied to the sock body or after construction, to create a special look. This may include lace, stitched monograms, embroidery, printed patterns or ironed-on decals.

Men’s

Available sizes:

Standard 7 to 12 shoe size

Men’s

Available sizes:

Standard 7 to 12 shoe size

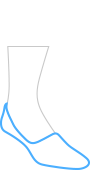

No Show

Socks that hide inside the shoe

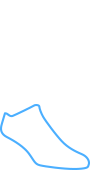

Liner

Socks that do not show above the shoe.

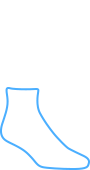

Quarter / Anklets

Socks with the top made to cover the ankle bone and extending less than one-third of the way up the largest part of the calf.

Mid-calf / Crew

Socks with a top extending over ankle length, but not beyond the largest part of the calf.

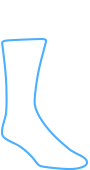

Over the calf / Executive

Socks with a top extending over the calf, but not over the knee

No Show

Socks that hide inside the shoe

Liner

Socks that do not show above the shoe.

Quarter / Anklets

Socks that touch the bottom of the ankle.

Mid-calf / Crew

Socks with the top made to cover the ankle bone and extending less than one-third of the way up the largest part of the calf.

Knee-high / trouser

Socks with a top extending over ankle length, but not beyond the largest part of the calf.

Construction & Finishing

Bleaching

It is the process where the color is removed from a fabric or a sock, leaving it white.

Boarding

This operation creates the shape of a sock. The sock is heated and formed on a board to form its shape and a smooth surface. This process appears to be very similar to ironing.

Circular Knit

The circular knit is the first knitting method for socks. A single or double cylinder knitting machine builds the sock in one single operation.

Course

This is the horizontal row of stitches across any knitted fabric

Cross Stretch

It is the measurement of the amount of across-the-leg (or foot) as well as the stretch in a sock.

Cuff

The cuff is the top opening of the sock. Most of the time, the socks has elastic added to hold the sock up.

Cushing

The cushing is any construction with a terry pile surface on one side and a ribbed or plain knit surface on the other.

Dyeing

It is the permanent application of colour to a yarn or fabric.

Electronic Patterning

This is the use of an electronic device to control certain needles in knitting to create a pattern.

Finishing

The final steps of finishing regroups all socks manufacturing steps after knitting: bleaching, scouring and dyeing, boarding, pairing, ornamentation, folding, and packaging.

Reciprocated

In the usual knitting process, the socks starts at the top and knitted toward the toe. When it gets close to the heel, the machines starts to move more slowly in a semi-circular (reciprocated) fashion to produce the heel pocket. Not all socks have reciprocated toes and heels.

Reinforced

Most of the time, toe and heel areas are often reinforced with nylon or polyester to improve abrasion resistance and increase durability.

Ribbed

This is the most common pattern for sock fabric. It is composed for vertical ridge or “wales”. Ribbing also provides an element of elasticity.

Scouring

This process is a soap bath that removes chemicals, tints, impurities and foreign matter from socks during finishing.

Softeners

A chemical agent added in the wash cycle to add extra softness.

Terry

This is a looped pile construction used inside most athletic socks and some work socks.

Toe Closure

There are various types of closure methods:

-

Hand Linked

This is a labour intensive process where loops are joined together by chain stitch. -

Lintoetm

It is an automatic simulated hand-linked toe closure. -

Rosso toe

This is a double stitched fine seam on the last course of knitting. -

Fishmouth Toe

It is a method for closing a non-reciprocated toe pocket in which the seam runs parallel to the bottom of the foot rather than across the top of the toe. It is mostly used on trouser socks and tight.

Tube

A tube sock is a symmetrically-knitted sock that has no heal or toe pocket, i.e. non-reciprocated heel and toe.

Wales

These are vertical row of stitches in a knitted construction.

Welt

It is a fabric knitted separately and machine-sewn to the top of the sock.

Join our community

Our Newsletter